We are proud to own one of the worlds most impressive telescoping cranes on the market, using the latest technology and materials.

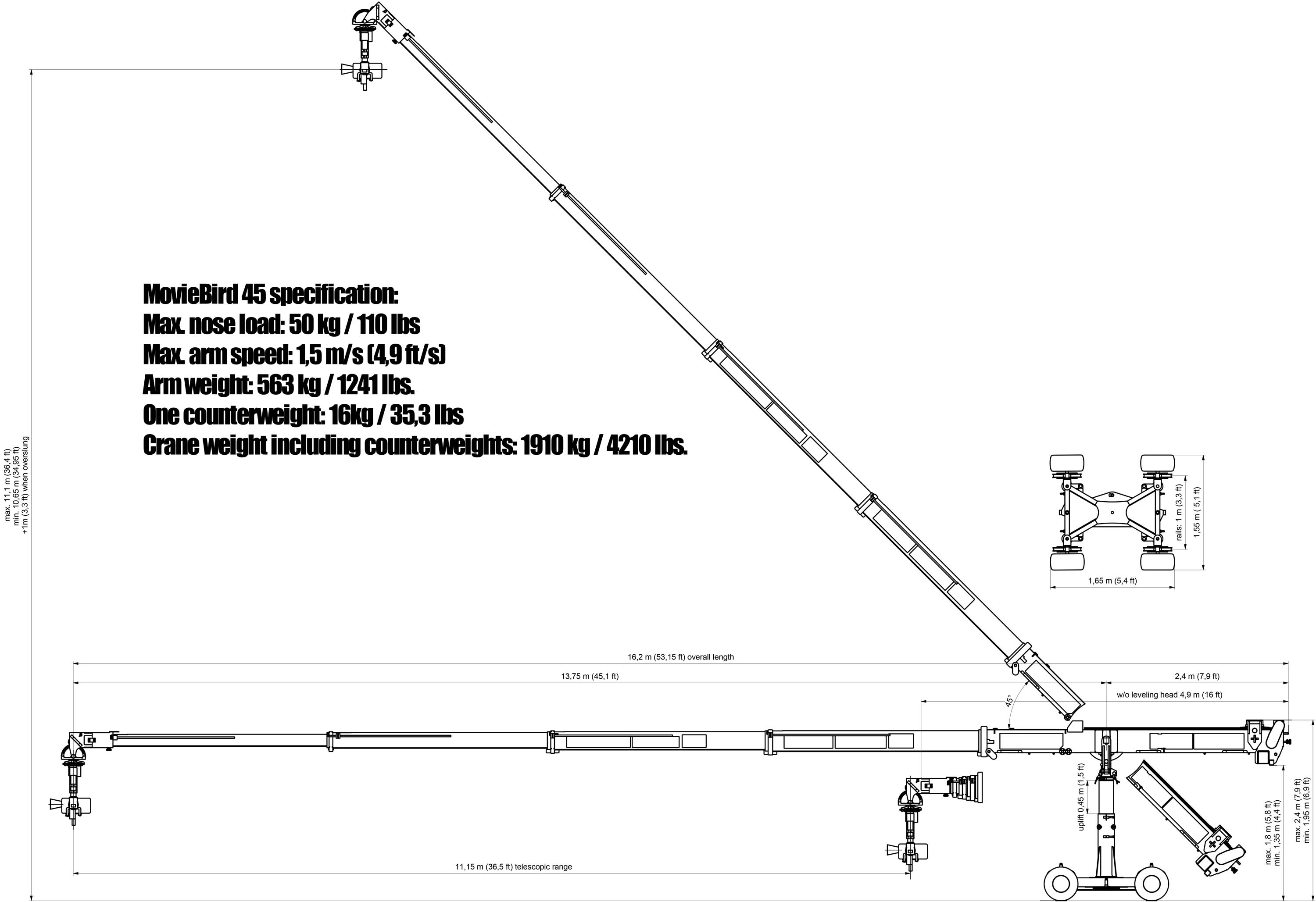

Τhis crane telescopes smooth, quiet and precise to make your shot more significant and polished than ever 45 feet [13.7 meters] of telescoping movement at a touch of a button.

The MB45’ is a relatively versatile telescopic crane suitable for any Film set or TV studio as this crane has the same dolly footprint as the smaller MB30 crane.

The MovieBird 45’ is fully compatible with all models of Remote Heads and all camera types from DSLR to IMAX also for special effects you can even mount moving light sources on it.

Owing to the cranes small weight and size when disassembled it can be transported in a standard 8,5 ton truck or a bespoke trailer. The Mb45 is currently the most desired telescopic crane available on the market today.